The filter cartridge winding machine is a cutting-edge technology that has transformed the filtration industry. This state-of-the-art machine automates and streamlines the process of manufacturing filter cartridges, resulting in improved efficiency and quality.

Enhancing Efficiency and Precision

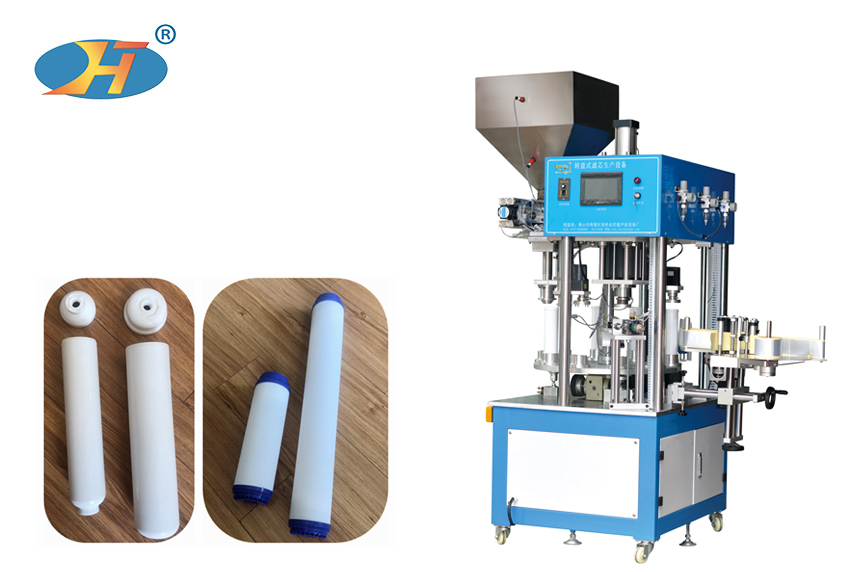

The filter cartridge winding machine utilizes advanced robotics and computer-controlled systems to wind filter media around a core, creating a tightly packed structure. This automated process ensures consistent tension control, precise alignment, and uniform distribution of the filter media.

By eliminating manual labor-intensive tasks, such as measuring and cutting the filter media, this machine significantly reduces production time while maintaining high accuracy. The result is an increase in productivity for manufacturers without compromising on product quality.

Innovations by Hongteng

Hongteng Machinery Co., Ltd., based in South Carolina, is one of the leading manufacturers of filter cartridge winding machines. With years of experience in research and development, Hongteng has introduced several groundbreaking innovations to enhance the performance of these machines.

Their latest models feature intelligent control systems that allow operators to easily adjust parameters such as winding speed, tension control, and layer thickness. Additionally, Hongteng’s machines are equipped with sensors that detect any abnormalities during production processes to ensure optimal performance at all times.

Pioneering PP Melt Blown Filter Machine

In response to increasing demand for high-quality filters with exceptional particle retention capabilities, Hongteng has also developed a revolutionary pp melt blown filter machine. This specialized equipment produces melt blown filters using polypropylene fibers arranged in a random web-like pattern.

The PP melt blown filter machine offers superior filtration efficiency by trapping even microscopic particles suspended in liquids or gases. This technology has found applications in various industries, including water treatment, pharmaceuticals, and food processing.

With the integration of the PP melt blown filter machine into their production line, manufacturers can now produce high-performance filters with ease and precision.

Conclusion

The filter cartridge winding machine has revolutionized the filtration industry by enhancing efficiency and precision in filter cartridge manufacturing. Innovations introduced by companies like Hongteng have further improved these machines’ capabilities, allowing for easy customization and optimal performance. The addition of the PP melt blown filter machine has expanded the range of filters that can be produced efficiently. With these advancements, manufacturers can meet growing demands for reliable filtration solutions across various sectors.