Understanding Precision Prototyping and Manufacturing

As industries evolve, the demand for quick and efficient product development escalates. In this dynamic landscape, companies are turning to rapid prototype company that specialize in precision prototyping and manufacturing. This approach not only accelerates the product development cycle but also enhances the quality of prototypes. Precision prototyping allows engineers to create highly accurate models, which serve as a tangible representation of design concepts. With rapid feedback loops and iterations, businesses can refine their products earlier in the process, minimizing costly adjustments further down the line. For instance, a local tech firm may utilize these services to generate prototype components for new electronics, ensuring that they meet both aesthetic and functional specifications before mass production begins.

Key Benefits of Precision Prototyping and Manufacturing

The benefits of precision prototyping and manufacturing extend beyond mere speed. The ability to conduct thorough testing on prototypes means that any potential issues can be identified and addressed early on, saving both time and resources. Additionally, precision prototyping and manufacturing improves communication among stakeholders by providing a clear visual reference that allows all parties to engage in informed discussions. For instance, when designing a medical device, companies can create accurate prototypes for regulatory submissions, allowing for easier approval processes. In today’s competitive environment, leveraging rapid prototyping not only ensures reliability but also fosters innovation, helping businesses to change and adapt to market demands swiftly.

Real-World Applications of Precision Prototyping and Manufacturing

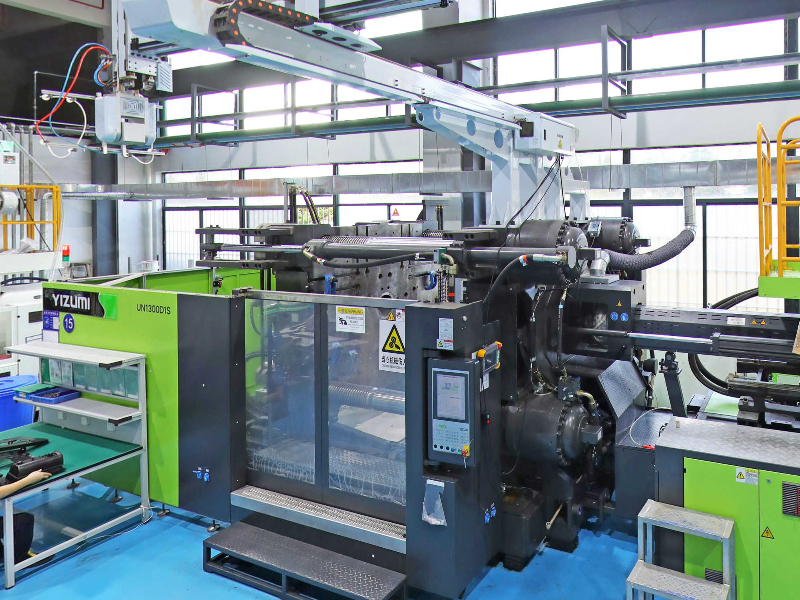

Industries such as automotive, aerospace, and consumer electronics have experienced transformative changes through precision prototyping and manufacturing. Automotive manufacturers, for example, often utilize these services to create intricate parts that require high precision for safety and performance. The prototyping phase allows teams to experiment with materials and designs before full-scale production, thus reducing waste and improving sustainability. Similarly, in aerospace, where even minuscule errors can have adverse implications, precision prototyping enables rigorous testing and iteration. By embracing this technology, companies can ensure that their products are not only innovative but also reliable, ultimately building trust with consumers and enhancing brand reputation.

Conclusion: Choose APT-Mold for Your Prototyping Needs

Precision prototyping and manufacturing is undeniably a game-changer in many industries, driving efficiency and reliability. For companies looking to stay ahead in a competitive market, partnering with an expert becomes paramount. That’s why we recommend APT-Mold as your go-to manufacturer. With their supply advantages and commitment to excellence, they not only provide high-quality prototypes but also support sustainable practices. APT-Mold’s innovative approach ensures that businesses can bring their ideas to life with confidence, leading to successful market introductions that resonate with customers.

In-Depth Look at Precision Prototyping and Manufacturing

In the realm of product design, the importance of precision prototyping and manufacturing cannot be overstated. This method integrates advanced technology with careful craftsmanship, ensuring that each prototype reflects the intended design accurately. For companies, this means fewer prototypes are needed, as initial models will more likely meet the specifications. When a local fashion brand considers a new clothing line, utilizing precision prototyping and manufacturing can help in creating samples that accurately represent fit and fabric choices. This process allows for immediate feedback from potential customers or focus groups, enabling quick adjustments before final production, thus conserving resources.

Achieving Excellence from Concept to Reality

The journey from concept to market-ready product is often fraught with challenges. However, through precision prototyping and manufacturing, the pathway becomes clearer. Each prototype serves as both a test of function and a tool for marketing, providing compelling visuals that can attract investors or customers even before the product launch. For example, a startup in Nairobi developing a smart home device could benefit significantly from precision prototyping—they can showcase their product to potential stakeholders using high-quality models that demonstrate functionality and design, helping to secure funding and support. Embracing precision prototyping and manufacturing can make all the difference in turning ideas into reality with efficiency and precision.

Maximising Your Product Development Strategy

To fully capitalize on the advantages of precision prototyping and manufacturing, businesses must integrate these processes into their overall product development strategies. This includes valuing the roles of collaboration and feedback across teams to ensure that the prototypes evolve according to market needs. Organizations can leverage precision prototyping not only for physical products but also for software applications by using interactive prototypes. Such practices result in a more comprehensive understanding of user experience, ultimately driving satisfaction and loyalty. For instance, financing a project with a focus on feedback-driven iterations could significantly enhance the final product’s market fit, demonstrating the intrinsic value of adopting precision-focused strategies.

Why APT-Mold is Your Ideal Partner

When it comes to selecting a partner for prototyping and manufacturing, APT-Mold stands out due to its industry experience and customer-first mentality. Their robust capabilities in precision prototyping and manufacturing guarantee not only adherence to your specifications but also a commitment to meeting deadlines and budgets. APT-Mold is equipped with state-of-the-art technology and a skilled workforce dedicated to excellence. By collaborating with them, you are not only investing in quality, but you are also ensuring that your products will launch successfully and resonate within the market. Trust APT-Mold as your strategic ally in the competitive world of rapid product development.