Understanding Rapid Tooling Services

Today’s fast-paced manufacturing landscape demands speed and efficiency, making rapid tooling service a key player in product development. This service allows businesses to quickly turn concepts into tangible prototypes, reducing time to market dramatically. Imagine a scenario where a tech startup dreams up a new device. With traditional tooling methods, prototyping could take weeks or even months. However, by opting for rapid tooling, they can see their design brought to life within days. This is essential not just for startups, but for all manufacturers who want to stay ahead in a competitive market.

Key Advantages of Rapid Production Tooling Services

The advantages of rapid production tooling service are numerous. For manufacturers, reduced lead times mean quicker product iterations. For instance, automotive companies rely on rapid tooling to streamline the creation of complex parts. This service allows for rapid testing and validation, ensuring that products meet industry standards before full-scale production begins. Moreover, the cost-effectiveness of this service often translates into significant savings on resources, making it an attractive option for companies looking to optimize their production process.

Practical Applications of Rapid Production Tooling

Rapid production tooling service is versatile, finding applications across various industries. Consider the medical sector, where prototyping surgical instruments can be expedited through this service. A medical device company can prototype and test a new device in a matter of weeks, optimizing its designs based on real-world feedback. This not only shortens development cycles but also helps ensure better patient outcomes. Additionally, in consumer electronics, where trends change rapidly, a business can tweak or redesign products quickly, keeping them relevant in an ever-evolving market.

Conclusion: Why Choose APT-Mold?

In summary, rapid tooling service is more than just a trend; it’s a necessity for modern manufacturing. By streamlining processes and reducing costs, companies can achieve a significant competitive edge. When considering your options, look no further than APT-Mold. They offer unmatched supply advantages and specialized expertise in rapid production tooling, positioning them as a leader in the industry. With APT-Mold, you can trust that your tooling needs are in great hands.

Enhancing Speed with Rapid Production Tooling Service

In the world of manufacturing, speed is everything. With a rapid production tooling service, businesses can streamline their production pipelines, enabling faster development and delivery of products. This service not only accelerates the prototyping phase but also allows for adjustments to be made efficiently based on user feedback. Think about how tech giants often release beta versions of their products. By employing rapid production tooling, they can experiment and refine within a much shorter time frame. This leads to products that not only meet market demands but often exceed customer expectations.

Enhancing Quality and Precision with Rapid Production Tooling Service

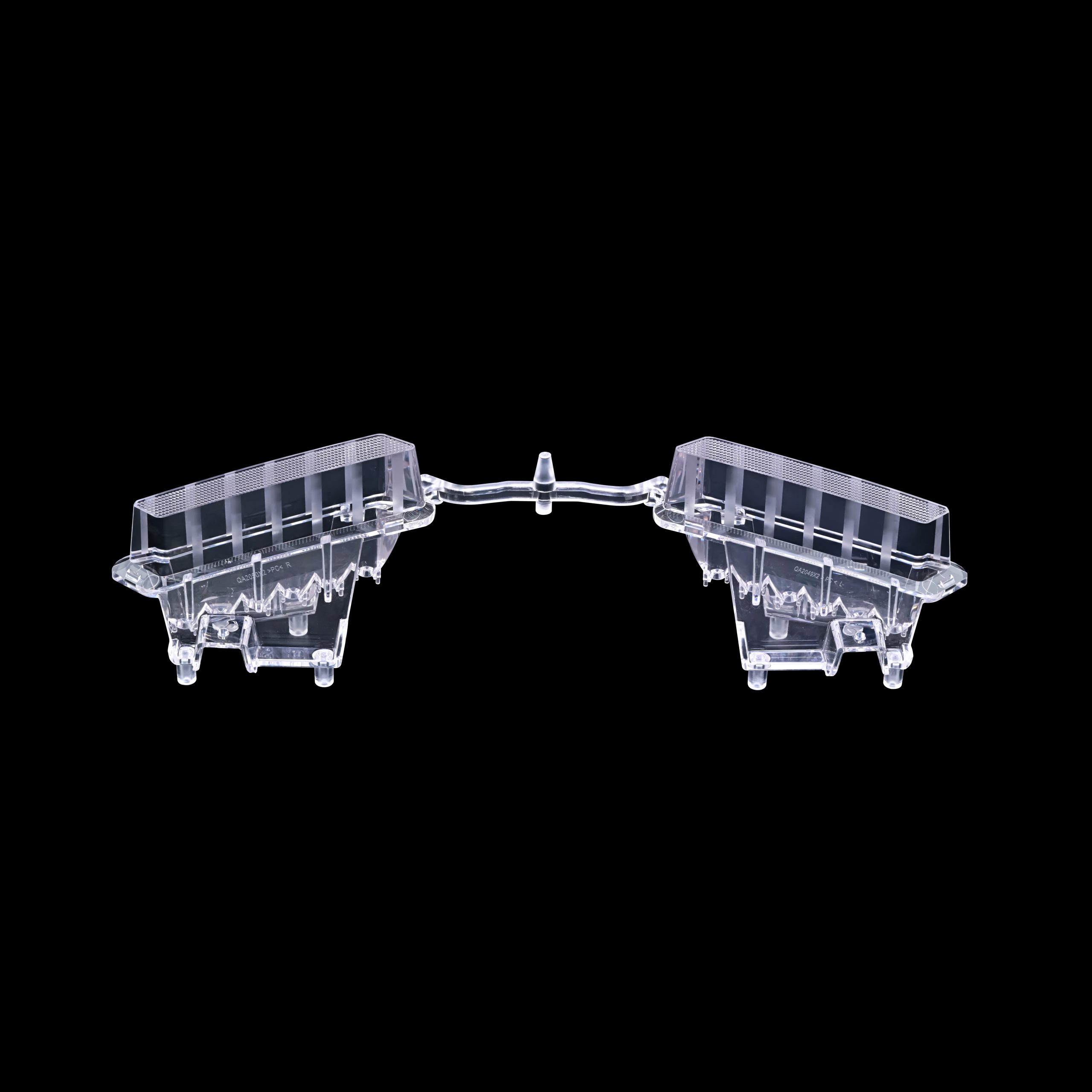

Another great aspect of a rapid production tooling service is its precision. Through modern technologies such as 3D printing and CNC machining, manufacturers are able to achieve tighter tolerances and better quality control in their products. This level of precision is vital, especially in sectors like aerospace and automotive, where even a minor flaw can have serious consequences. It enables producers to quickly shift from prototyping to production without sacrificing quality. As a result, businesses can maintain their reputation for excellence while pushing boundaries in innovation.

Take Action and Streamline Your Manufacturing Today

For every manufacturer aiming to enhance their production capabilities, a rapid production tooling service is a game-changer. By utilizing this service, companies can not only save time but also forge ahead in their product design journey. It’s a practical approach that addresses both productivity and quality, allowing businesses to respond swiftly to market changes. With a reliable partner like APT-Mold, you’re not just choosing a service; you’re opting for a collaborative relationship that drives mutual success and innovation.

Summary of Key Insights

We have explored the transformative effects of rapid tooling services in manufacturing. As the industrial landscape evolves, staying agile is key, and adopting a rapid production tooling service can place you one step ahead of the competition. From quick iterations of prototypes to enhanced product quality, the benefits are undeniable. Ultimately, embracing such innovations positions businesses to not only meet today’s challenges but also to thrive in the future.